The essence of snow-melting agents is that they are "phase change regulators" that lower the freezing point by altering the phase change mechanism of water. This characteristic, while different in app...

READ MORETexture Powder Additive, Micronized Wax Powder Additive

Texture powder additive and wax powder additive are common functional additives in coatings, primarily used to improve the feel, surface finish, and abrasion resistance of coatings. They enhance the physical properties of the coating, providing unique surface effects such as slip resistance, abrasion resistance, and a more tactile surface texture. These additives are widely used in coating systems requiring specific surface feel and durability.

Texture powder additive typically consists of coarse inorganic particles. When added to coatings, it creates a rough, granular surface, providing a certain degree of slip resistance. By increasing the surface roughness of the coating, it improves the coefficient of friction, resulting in better slip resistance. It is widely used in floor coatings, industrial coatings, and some exterior coatings. Furthermore, texture powder can improve the abrasion resistance and scratch resistance of coatings, making it suitable for high-frequency use surfaces such as industrial equipment, traffic markings, and floors.

Wax powder additive, on the other hand, is usually made from synthetic or natural waxes. When added to coatings, it provides a smooth, delicate surface finish and improves the coating's abrasion resistance. The main function of wax powder is to reduce the coefficient of friction of the coating through its unique surface properties, thereby enhancing the coating's scratch resistance, stain resistance, and self-cleaning properties. In coatings requiring high gloss or an extremely fine surface texture, the use of wax powder helps to enhance the smoothness of the coating and improve its stain resistance and fingerprint resistance. It is commonly used in furniture coatings, automotive coatings, and some household appliance coatings.

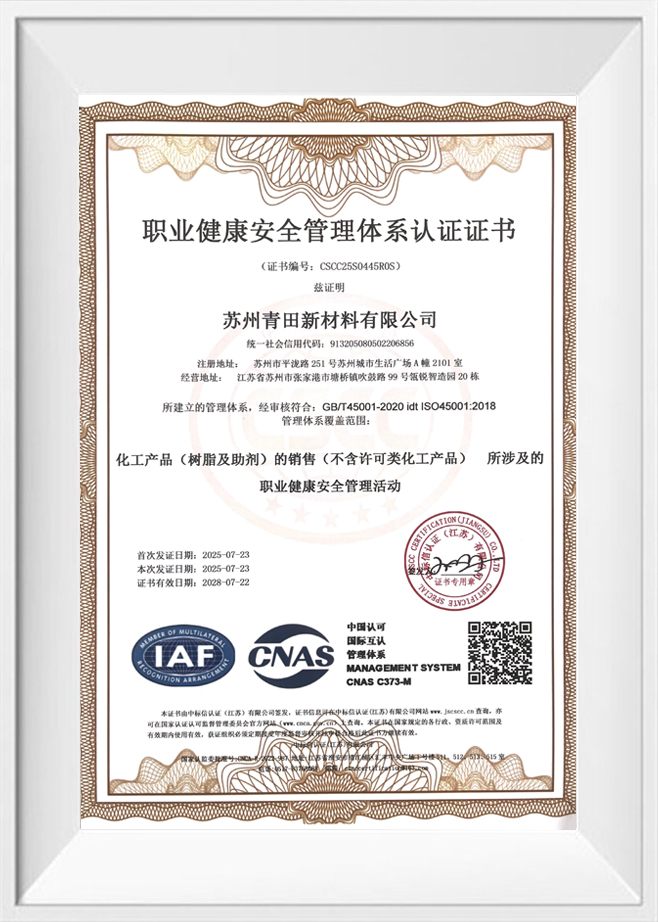

Suzhou Qingtian New Material Co., Ltd. is a professional company specializing in raw materials for coatings, inks, and adhesives. Through years of effort, the company has developed a professional R&D team, sales team, and production base, equipped with comprehensive testing equipment and cutting-edge technical R&D personnel, striving tirelessly to serve customers and lead the market.

The company's main products include dispersants, leveling agents, defoamers, adhesion promoters, anti-settling agents, cooling agents, conductive agents, orange peel texture agents, texture powders, and wax powders. The products have a wide sales range, covering steel and aluminum coil coatings, plastic coatings, UV curing, anti-corrosion coatings, wood coatings, glass coatings, epoxy flooring, printing inks, power batteries, photovoltaic panels, and other fields. In response to the national environmental protection concept of "clear waters and blue skies," the company continuously innovates and develops water-based products, contributing to the development of the water-based industry.

Qingtian New Material adheres to the business philosophy of "Professionalism, Integrity, Service, and Win-Win," and has adopted advanced international marketing concepts and market management models to provide high-quality products and services to new and old customers, achieving win-win results with trustworthy partners.

-

-

First Generation: Sodium Chloride – A Classic “Pioneer” Industrial salt is a relatively traditional and economical de-icing agent. Raw materials are readily available, costs are low, and it works well...

READ MORE -

The macroscopic properties of materials are a reflection of their microscopic structure. The brittleness of polylactic acid (PLA) is determined by its molecular and aggregated characteristics, and coa...

READ MORE

English

English