The essence of snow-melting agents is that they are "phase change regulators" that lower the freezing point by altering the phase change mechanism of water. This characteristic, while different in app...

READ MOREMicronized PTFE Wax Powder Additive

Polytetrafluoroethylene (PTFE) wax additive is widely used in coating systems requiring resistance to wear, adhesion, and chemical corrosion. Its main principle is that its low coefficient of friction and chemical inertness allow it to form a robust protective film on the coating surface, effectively improving the coating's wear resistance, anti-adhesion properties, and chemical corrosion resistance.

The molecular structure of PTFE wax powder gives it an extremely low coefficient of friction, significantly reducing friction between the coating surface and objects, minimizing wear and scratches, and extending the coating's service life. Furthermore, the chemical inertness of PTFE makes it resistant to most acids, alkalis, and solvents, resulting in excellent corrosion resistance in harsh chemical environments. The addition of wax powder forms a protective film on the coating surface, effectively isolating it from external chemicals and reducing the risk of corrosion, oxidation, or degradation.

Due to the high-temperature resistance of PTFE wax powder, it can withstand use in high-temperature environments without losing its protective function. This makes it important in high-temperature coating systems, especially in the surface protection of equipment and materials requiring high temperature resistance, such as high-temperature pipeline coatings, automotive engine component coatings, and metal industry coatings.

The anti-adhesion properties of polytetrafluoroethylene wax powder also enable it to play a role in certain coating systems, especially in coatings that need to prevent the adhesion of substances (such as oil, dust, etc.), such as in food processing, pharmaceutical, and chemical equipment, where it can keep the coating surface clean and smooth for a longer period of time.

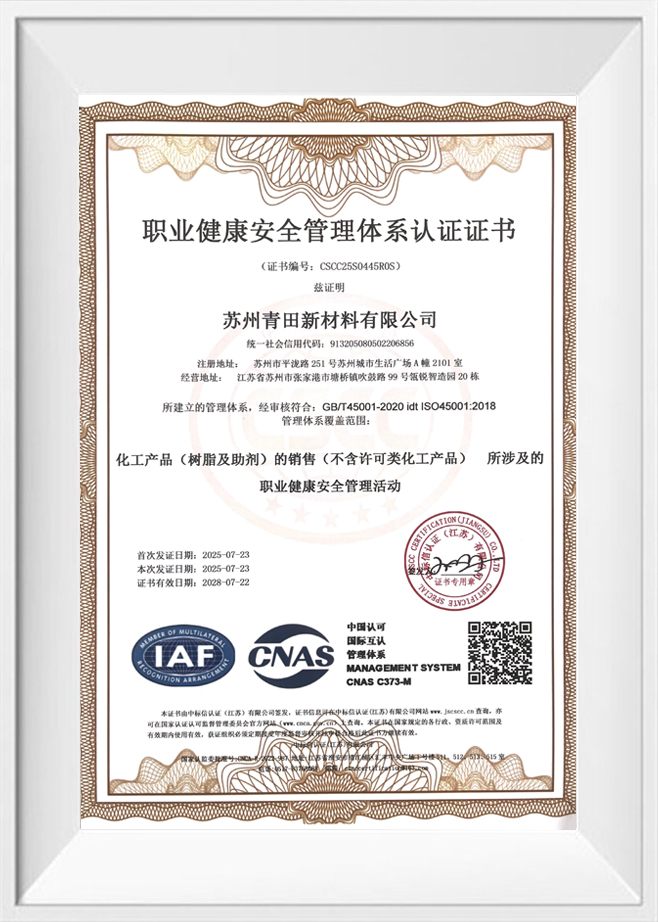

Suzhou Qingtian New Material Co., Ltd. is a professional company specializing in raw materials for coatings, inks, and adhesives. Through years of effort, the company has developed a professional R&D team, sales team, and production base, equipped with comprehensive testing equipment and cutting-edge technical R&D personnel, striving tirelessly to serve customers and lead the market.

The company's main products include dispersants, leveling agents, defoamers, adhesion promoters, anti-settling agents, cooling agents, conductive agents, orange peel texture agents, texture powders, and wax powders. The products have a wide sales range, covering steel and aluminum coil coatings, plastic coatings, UV curing, anti-corrosion coatings, wood coatings, glass coatings, epoxy flooring, printing inks, power batteries, photovoltaic panels, and other fields. In response to the national environmental protection concept of "clear waters and blue skies," the company continuously innovates and develops water-based products, contributing to the development of the water-based industry.

Qingtian New Material adheres to the business philosophy of "Professionalism, Integrity, Service, and Win-Win," and has adopted advanced international marketing concepts and market management models to provide high-quality products and services to new and old customers, achieving win-win results with trustworthy partners.

-

-

First Generation: Sodium Chloride – A Classic “Pioneer” Industrial salt is a relatively traditional and economical de-icing agent. Raw materials are readily available, costs are low, and it works well...

READ MORE -

The macroscopic properties of materials are a reflection of their microscopic structure. The brittleness of polylactic acid (PLA) is determined by its molecular and aggregated characteristics, and coa...

READ MORE

English

English